Trusted Ball Valve Manufacturers and Suppliers for India’s Oil and Power Industries

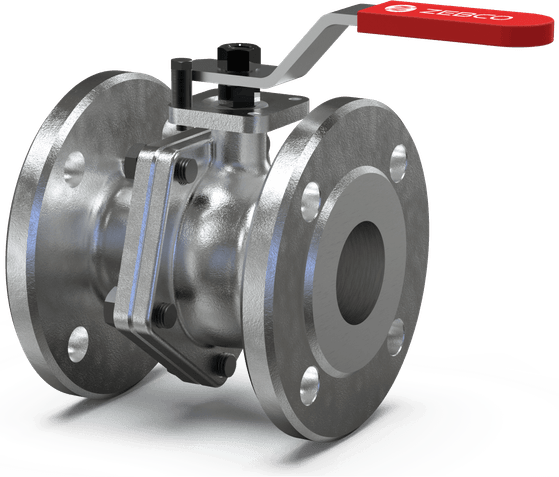

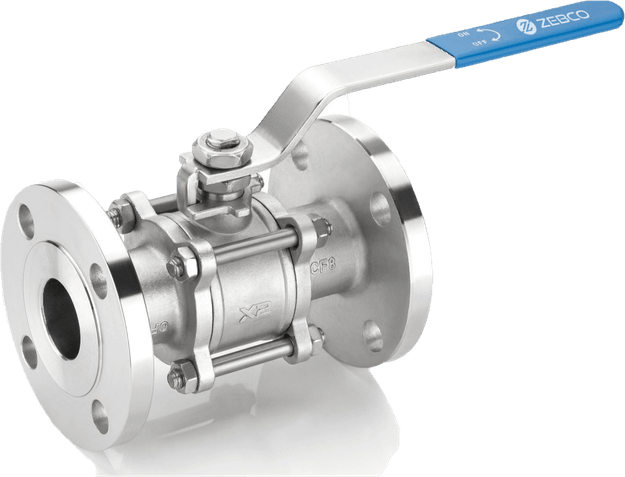

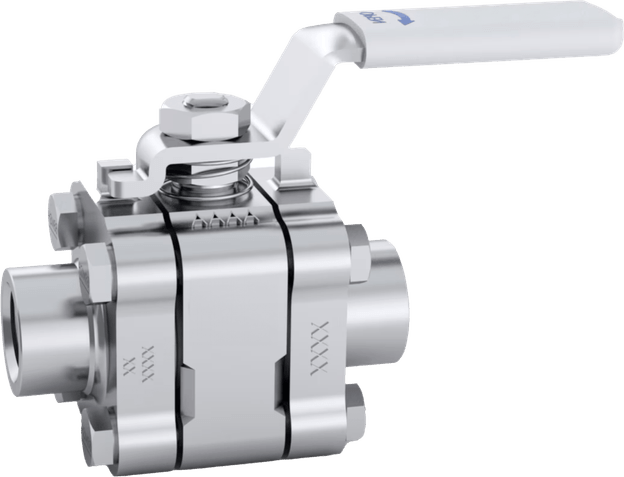

At Zebco Engineering, we specialize in offering durable and high-performance ball valves for industries such as oil, gas, petrochemicals, and power. Our range includes floating and trunnion-mounted ball valves, designed for precise flow control and reliable operation in demanding conditions.

Industrial Ball Valve Manufacturer in India | Zebco

Zebco manufactures high-performance ball valves in India, designed for precise flow control and long-lasting durability. Trusted by industries, our ball valves deliver unmatched reliability and efficiency for diverse applications.

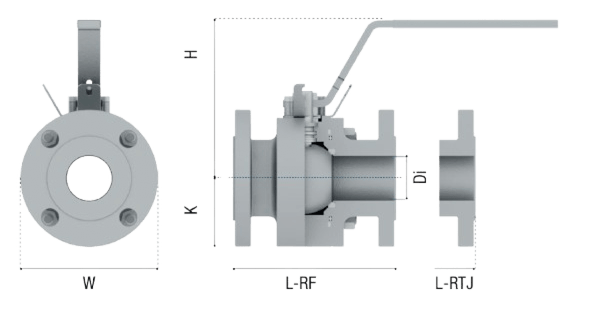

| DESIGN | : | API 6D/ASME B16 |

| FACE TO FACE | : | ASME B 16.10/API 6D |

| END TO END | : | W / BW / Flanged / RTJ ends |

| PRESSURE - TEMP. RATING | : | ASME B 16.34 |

| MATERIALS (BODY | BONNET) | : | 3 Pieces/ 4 Pieces Design - CS/ SS/ALLOY STEEL/ DSS/ NI-ALLOYS/ BRONZE |

| FLANGE END | : | ASME B 16.5 |

| TEST STANDARD | : | API 6D / API 598 |

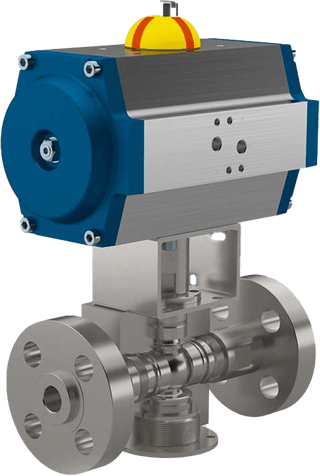

| OPERATION | : | Manual | Gear | Actuated |

| Size | : | 1/2'-12' (15mm - 300mm) |

| Class | : | 150# - 2500# |

INTRODUCTION TO BALL VALVES: KEY TO SEAMLESS FLOW CONTROL

TRUSTED MANUFACTURER, EXPORTER, AND SUPPLIER OF ball VALVE IN India

At Zebco, we take pride in offering high-quality ball valves, including our API 6D trunnion-mounted models up to 42” for critical processes. With years of expertise and advanced infrastructure, we’re capable of designing even larger valves to meet your unique requirements.

Our valves are available in both soft-seated and metal-seated options, ensuring zero leakage and reliable performance in high-temperature, cryogenic, and abrasive environments. The top-entry trunnion valves are designed for easy in-line maintenance, minimizing downtime and maximizing efficiency.

We offer both bolted and welded construction options, with welded valves being perfect for buried services. Each valve undergoes fire-safe testing and meets fugitive emission standards. With an ASME Class range from 150 to 2500, we also provide CE marking and SIL certification, ensuring added reliability and peace of mind.

Our ball valves are equipped with features like double block and bleed, automatic cavity relief, anti-blowout stem design, and lip seals for low-temperature use as standard. For even more demanding applications, we offer the double piston effect (DPE) for enhanced sealing. Zebco ball valves can also be fitted with Electric, Electro-Hydraulic, Pneumatic, and Gas-over-Oil actuators, providing flexible solutions for various operational needs.

THE KEY BENEFITS OF BALL VALVES: RELIABLE, EFFICIENT, AND EASY TO USE

- Reliable Performance: Zebco ball valves offer a tight seal with minimal leakage, giving you peace of mind that your fluid control is safe and efficient, every time.

- Versatile Applications: Whether it's oil and gas, petrochemicals, water treatment, or power generation, our valves are designed to adapt to a wide range of industries and challenging environments.

- Easy Operation: With their smooth, quarter-turn design, Zebco ball valves make it easy to control and operate your systems, even in the most complex setups.

- Durability: Built tough, Zebco ball valves are engineered to endure high pressure, extreme temperatures, and abrasive conditions, ensuring long-lasting performance in even the harshest environments.

- Minimal Maintenance: The simple, efficient design of our valves reduces the need for frequent maintenance, keeping your operational costs down and minimizing downtime.

- Quick Response: Need fast, precise flow control? Our ball valves open and close quickly, giving you the flexibility to respond swiftly to changing demands.

- Fire Safe and Emission Compliant: Zebco ball valves are fire-safe tested and meet fugitive emission standards, so you can rest assured your operations are both safe and environmentally responsible.

- Customizable: No two industries are the same, so we offer a variety of actuation options—Electric, Pneumatic, and Hydraulic—to perfectly fit your specific operational needs.

- Zero Leakage: With both soft-seated and metal-seated configurations, our ball valves ensure a reliable, leak-free seal, even for critical applications that require tight shut-offs.

- At Zebco, we don’t just manufacture valves—we create reliable, tailored solutions designed to make your operations run smoother and more efficiently.

BALL VALVE CONSTRUCTION: THE KEY TO LONG-LASTING PERFORMANCE

The Swing Check Valve is a one-piece body, top entry design for reliable operation and extended seat seal life. Top entry construction allows field service and in-line maintenance if necessary. All major components of the check valve are normally made from cast and wrought forms, allowing the use of a variety of widely accepted materials. The full bore to API-6D assures unrestricted flow and allows pigging and hot tapping.

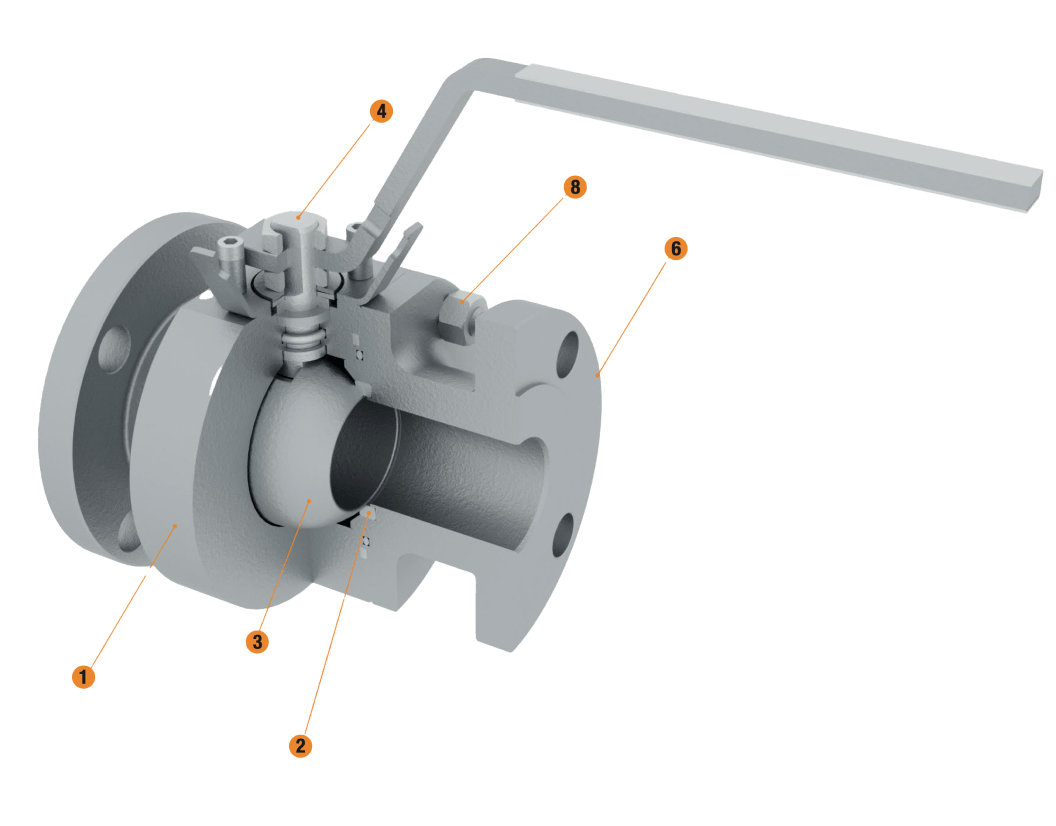

FORGED STEEL, SIDE ENTRY SPLIT BOLTED BODY, SEAT SUPPORTED FLOATING BALL, SOFT OR METAL SEATED, ANTI BLOW-OUT STEM, ANTISTATIC DEVICE, FIRESAFE DESIGN

| 1. BODY | The body is forged in carbon, stainless and other CRA steels commonly used in the O&G industry suchas Duplex, Super Duplex and Nickel Alloys . Its design is in compliance with the relevant API and ASMEStandards. Threaded plugged connections are provided for the vent and drain functions. |

|---|---|

| 2. SEAT RINGS | Floating, renewable metallic rings are supplied as a standard with a soft thermoplastic insert that provides a Zero Leakage seal. Insert material is selected based on valve pressure/temperature design conditions. Springs keep the seats pushed against the ball to ensure a tight seal at low pressure and allow the same to slide back to release any overpressure in the body cavity (Single Piston Effect). In some instances seat rings can be required to effect a double seal – from the line as well as from the body cavity – (Double Piston Effect). In this case a relief valve may be required to release the cavity overpressure. For special services (slurry, presence of solids, high temperature) the soft insert can be replaced by a hard facing with Tungsten or Chrome Carbides Coating (Metal Seated). |

| 3. BALL | The ball is supported and guided by an external trunnion ( sizes ≤ 6” RB ) or internal trunnion plates (sizes ≥ 6” FB). It makes a 90° movement from the fully open to the fully closed position driven by the stem connected to a slot in the ball. Its circular opening allows for minimal pressure losses and, in Full Bore execution, for the passage of inspection/cleaning devices (Piggable). In metal seated execution the sealing area of the ball is also coated with Tungsten or Chrome Carbides and lapped with the seats to obtain a tight sealing. |

| 4. STEM | The stem is designed to comply with relevant API Standard requirements. It is inserted from inside the body through the bonnet and the adapter plate to connect with the operator and its shouldered design ensures that it cannot be ejected by the internal pressure (Anti Blow-Out). It houses the stem sealings, either elastomeric O-Rings or thermoplastic Lip Seals, designed to meet the most stringent Fugitive Emissions requirements. A Graphite ring integrates the set of sealings as a Firesafe barrier. |

| 5. BONNET | The bonnet is fixed to the body by means of cap screws. Its internal surfaces are the sealing areas of the dynamic stem seals and can be overlayed with CRA to prevent corrosion and ensure sealing continuity over time against aggressive media. |

| 6. CLOSURES | The closures are bolted to the body by means of fully threaded studs and nuts. They are machined to the specified ends ( Flanged, Butt Weld, Hub ) for connection to the line. The closures accommodate the springs and the seat rings and, same as the bonnet, can be internally overlayed with CRA in the area of the seat dynamic seals. |

| 7. ADAPTER PLATE | The adapter plate is the upper flange for connection to the operator, either Gear or any type of Actuator. It is designed and sized in accordance with ISO 5211. |

| 8. BODY BOLTING | Body studs and nuts are supplied in materials according to ASTM standard and can be coated to any special requirement. The body to closure connection is designed according to ASME VIII Div. 1 |

BALL VALVE

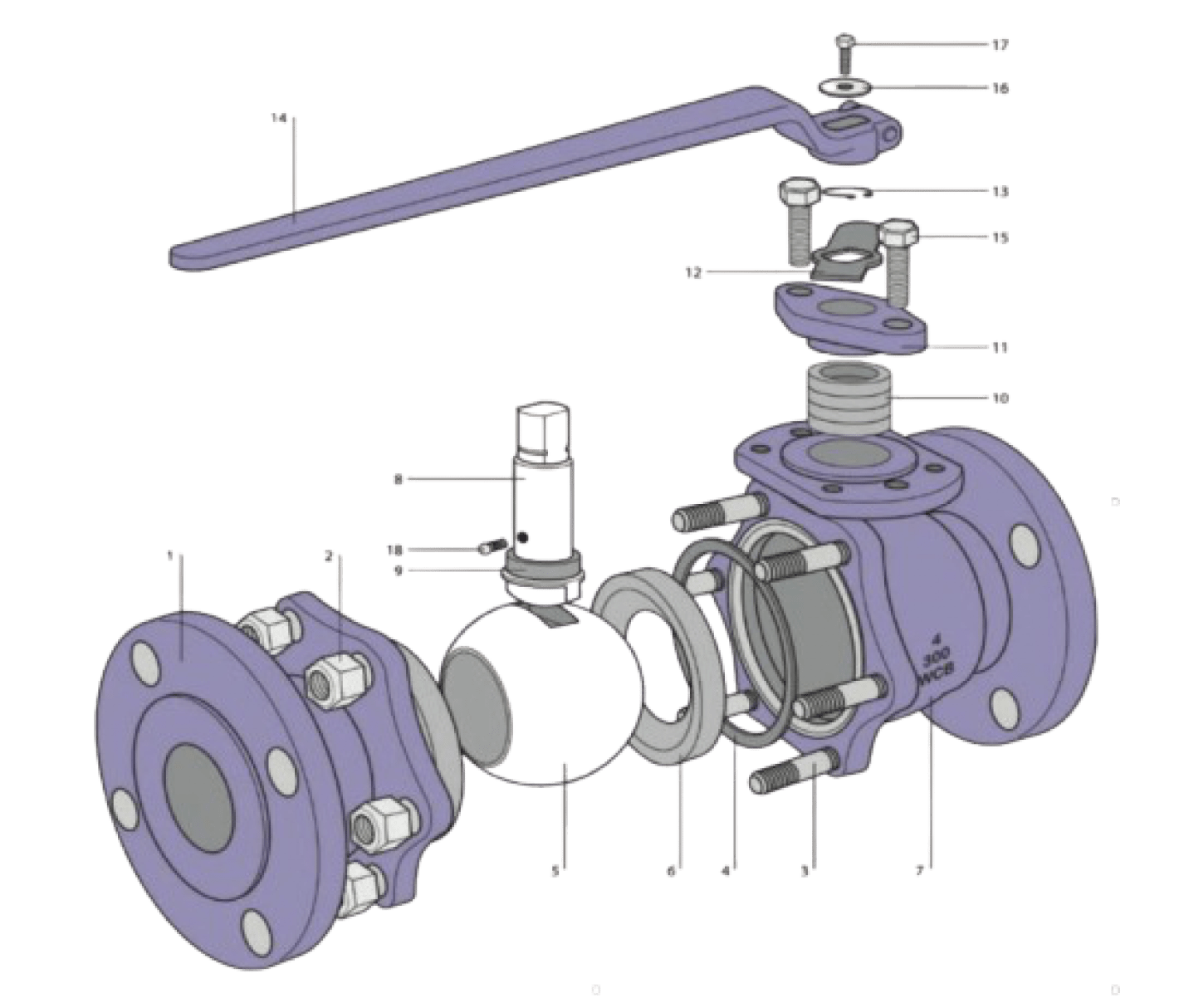

| No. | Name of Part | CARBON STEEL | STAINLESS STEEL |

|---|---|---|---|

| 1 | Body End Cap | ASTM A216 - WCB | ASTM A351-CF8M |

| 2 | Nut | Carbon Steel/GR.2H | AISI/ASME 304/GR.8 |

| 3 | Body Joint Bolt | Carbon Steel/GR.B7 | AISI/ASME 304/GR.B8 |

| 4 | Body Gasket | PTFE | PTFE |

| 5 | Ball | ASTM A351-CF8M/316 | ASTM A351-CF8M/316 |

| 6 | Seat | PTFE | PTFE |

| 7 | Body | ASTM A216 - WCB | ASTM A351-CF8M |

| 8 | Stem | ASTM A276-316 | ASTM A276-316 |

| 9 | Stem Thrust washer | PTFE | PTFE |

| 10 | Stem Packing | PTFE | PTFE |

| 11 | Gland Flange | ASTM A351-CF8 | ASTM A351-CF8 |

| 12 | Handle Stop | AISI/ASME 304 | AISI/ASME 304 |

| 13 | Snap ring | AISI/ASME 420 | AISI/ASME 420 |

| 14 | Handle | Carbon Steel | Carbon Steel |

| 15 | Gland Bolt | AISI/ASME 304 | AISI/ASME 304 |

| 16 | Washer | AISI/ASME 304 | AISI/ASME 304 |

| 17 | Cap Screw | AISI/ASME 304 | AISI/ASME 304 |

| 18 | Anti-static Device | 316SS | 316SS |

Industries We Serve

Zebco Engineering proudly serves a diverse array of industries, including manufacturing, energy, oil & gas, and more. Our products are designed to meet the highest standards across every sector we support.

Let’s Get Started

Our team is here to help with all your industrial needs. Reach out to us today, and let Zebco Engineering provide the solutions you're looking for.

Need Expert Assistance?

Complete the Form and We'll Reach Out Soon!