Your Trusted Butterfly Valve Manufacturer, Supplier & Authorized Dealer in India

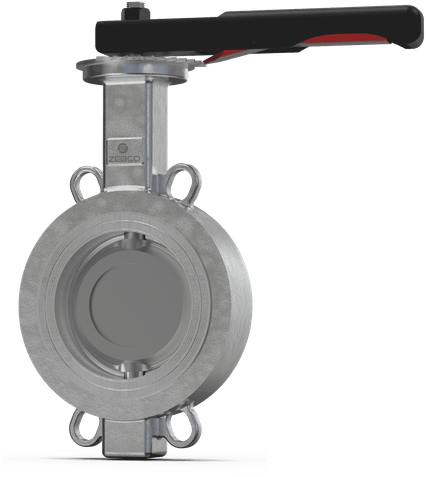

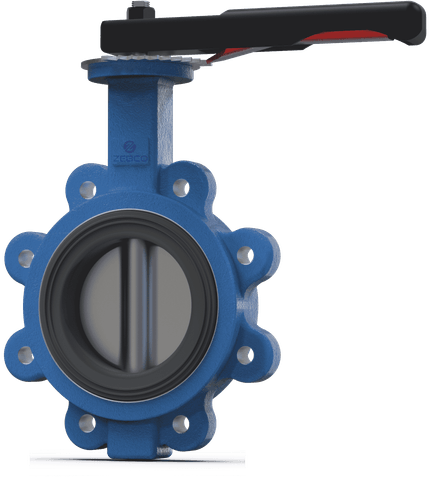

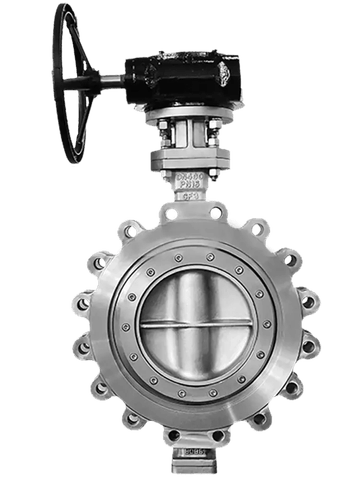

Zebco, known for manufacturing API-grade butterfly valves, offers a range of options such as lug, wafer, and triple-offset valves, delivering durable and efficient flow control solutions for India's oil & gas, petrochemical, and power generation sectors.

Reliable Butterfly Valve Manufacturer in India | Zebco

Zebco is a leading manufacturer of butterfly valves in India, offering wafer, lug, flanged, and triple-offset designs. Our valves are built for durability and precise flow control, delivering reliable solutions across various industrial sectors.

| Design | : | API 609 , ANSI B16.34 , BS 5155 |

| Face to Face | : | API 609 , BS 5155 , ANSI B16.10 |

| End to End | : | Wafer, Lugged, Flanged |

| SPECIALITY | : | Double Offset / Tripal Offset |

| MATERIALS (BODY | BONNET) | : | CS / SS / Alloys / Monel / Hastalloys / Bronze MOC |

| MOUNTING FLANG | : | ISO5211 |

| TEST STANDARD | : | API 598, BS 5155 |

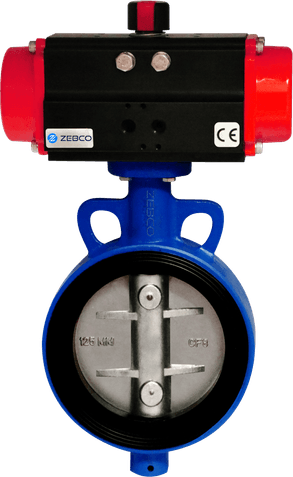

| OPERATION | : | Lever | Gear | Pneumatic operated | Electrical Actuated |

| Size | : | 1 -36 (15NB - 900NB) |

| Class | : | 150#-600#, PN10, PN16, PN25, PN40 |

BUTTERFLY VALVES: SIMPLE, EFFICIENT, AND ESSENTIAL FOR YOUR OPERATIONS

TRUSTED MANUFACTURER, EXPORTER, AND SUPPLIER OF Butterfly Valve VALVE IN BAHRAIN

Zebco is your go-to partner for high-performance butterfly valves, trusted by industries worldwide. Designed for easy installation, low maintenance, and precise fluid control, our valves are built to handle the most demanding applications. With a wide range of sizes and pressure ratings, they are crafted from robust materials and meet stringent API standards to deliver unmatched durability and reliable performance.

We offer various types of butterfly valves to cater to different needs. For low-pressure systems, our Centric (Resilient-Seated) Butterfly Valves provide excellent sealing. Double Eccentric (High-Performance) Butterfly Valves are perfect for medium-pressure applications, while Triple Eccentric (Metal-Seated) Butterfly Valves excel in high-pressure, high-temperature environments. Additionally, our Wafer-Type Butterfly Valves are ideal for space-saving installations, and Lug-Type Butterfly Valves make installation and maintenance a breeze.

At Zebco, we’re committed to providing reliable, efficient, and cost-effective solutions. Let us help you find the perfect butterfly valve for your operations. Reach out today to explore our range!

BUTTERFLY VALVES: KEY BENEFITS FOR SMOOTH & EFFICIENT OPERATIONS

- Precise Flow Control: Butterfly valves allow for fine control of fluid flow, helping ensure your system operates smoothly with minimal pressure loss. This makes them perfect for applications that require precise adjustments.

- Minimal Leakage: Thanks to their advanced sealing technology, butterfly valves provide a reliable, tight seal, reducing the risk of leaks and improving system efficiency.

- Versatile Materials: Butterfly valves are available in a wide range of materials, including stainless steel, cast iron, and plastic, making them adaptable for use in different environments, from corrosive chemicals to high temperatures.

- Easy to Integrate: Whether you're working on a new installation or retrofitting an old system, butterfly valves are simple to integrate, saving time and effort.

- Enhanced Safety Features: Many butterfly valves come with fire-safe designs and additional safety mechanisms, providing peace of mind even in high-risk situations.

- Long-Lasting Durability: With the right care, butterfly valves offer a long service life, giving you dependable performance year after year.

- Built for Tough Conditions: Designed to withstand heavy-duty applications, butterfly valves are perfect for high-cycle operations and harsh environments.

- Reduced Turbulence: Their streamlined design reduces fluid turbulence, improving flow efficiency and helping you save on energy costs.

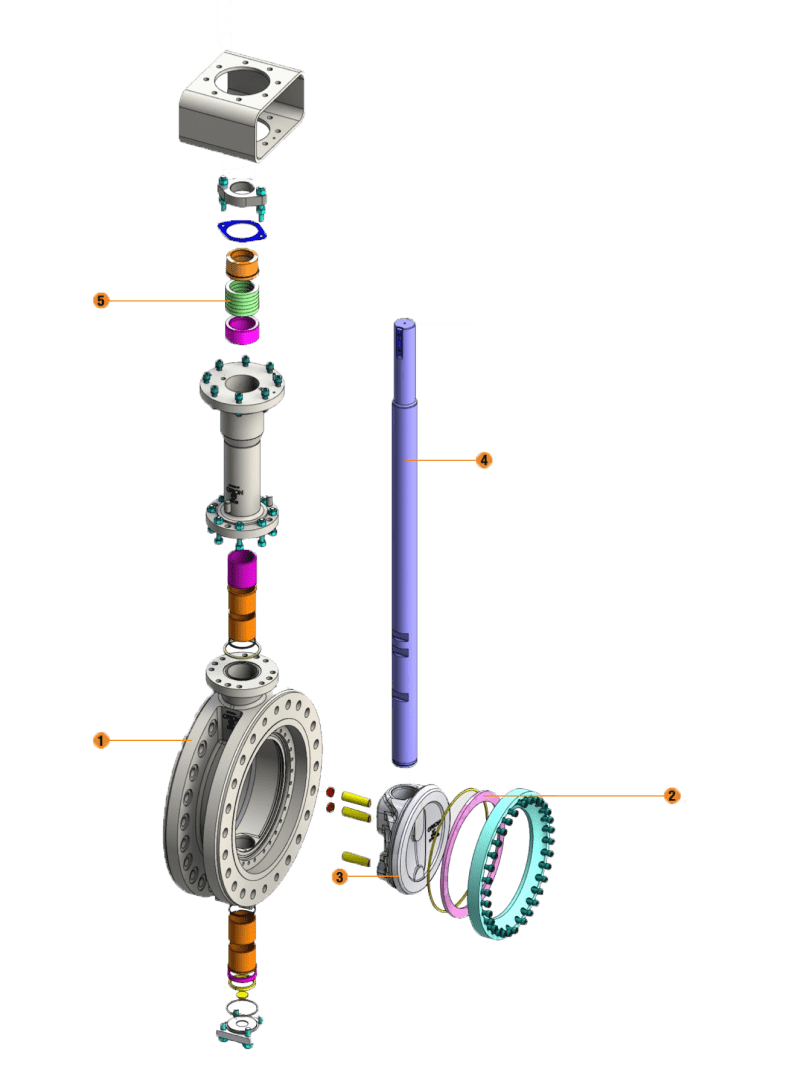

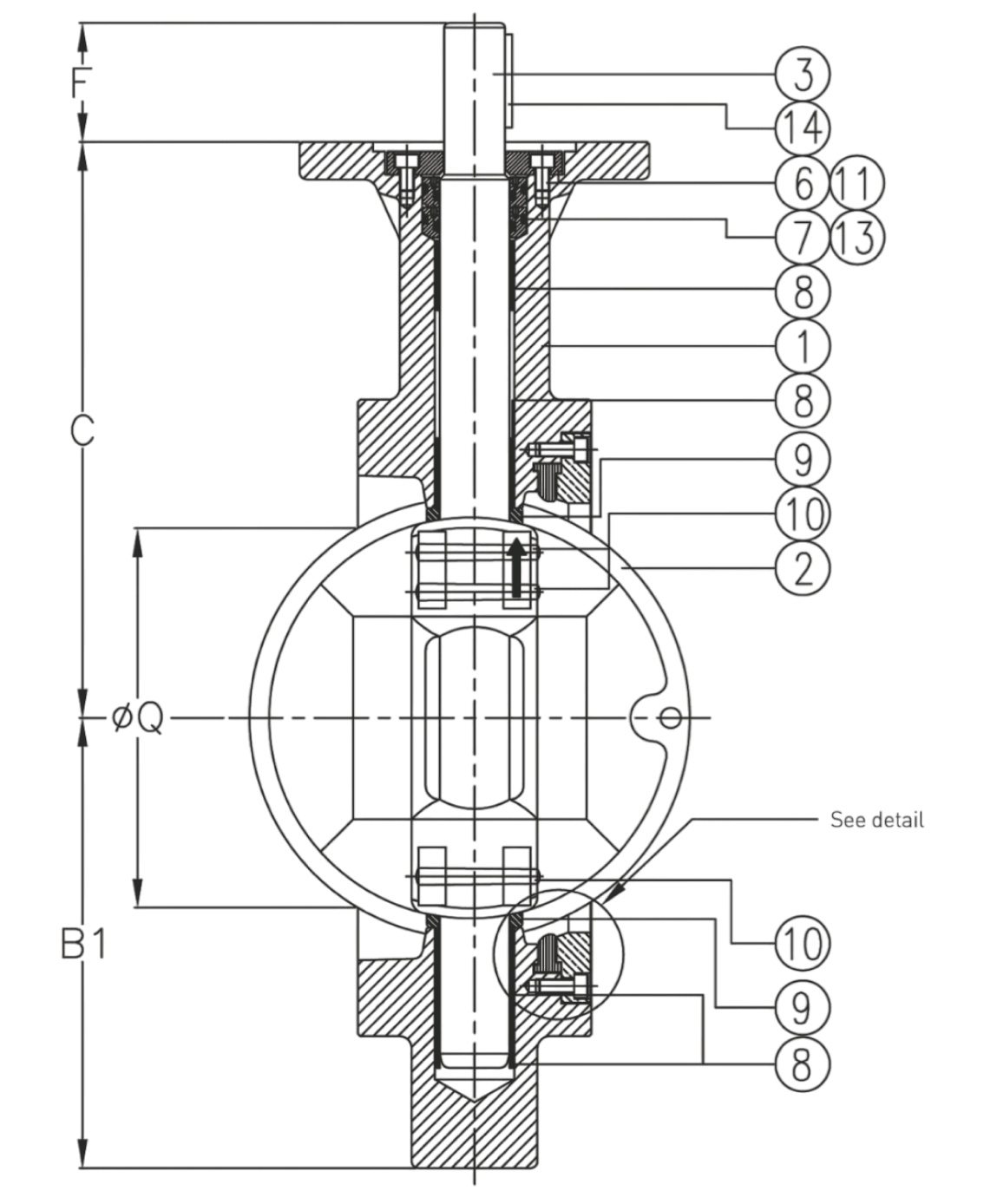

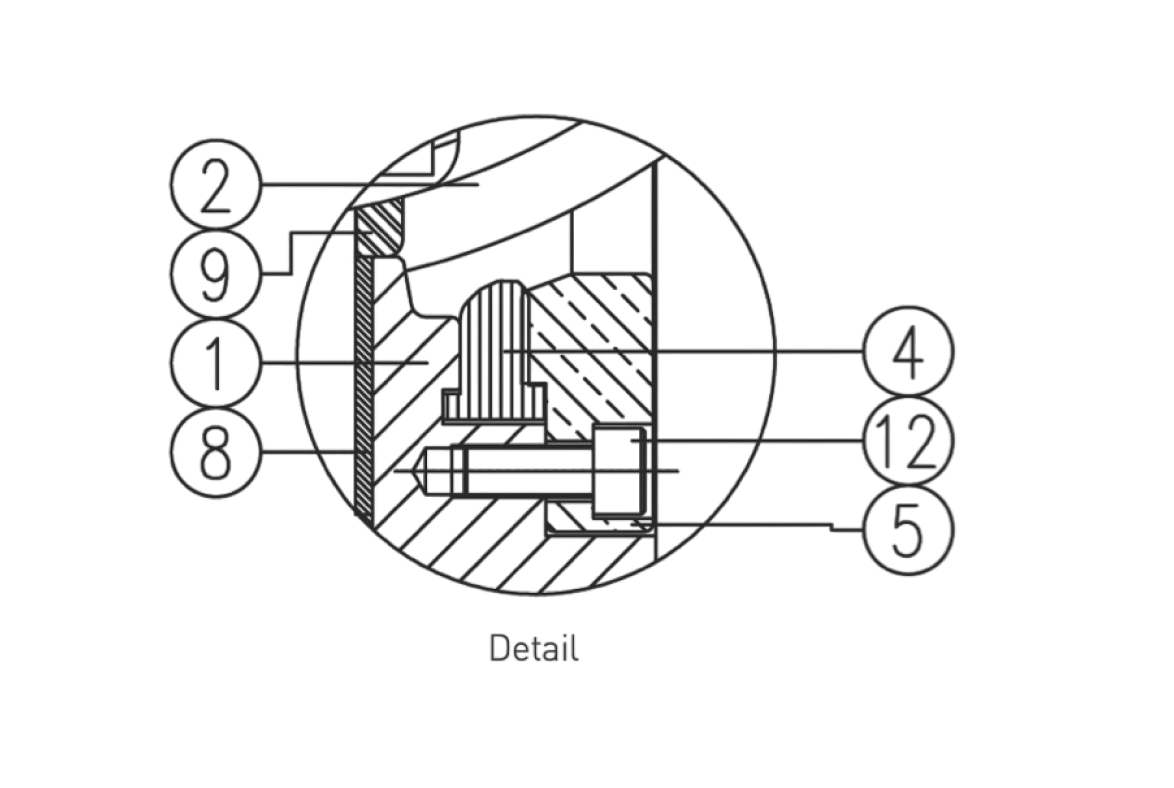

INSIDE A BUTTERFLY VALVE: SIMPLE AND EFFECTIVE DESIGN

The Swing Check Valve is a one-piece body, top entry design for reliable operation and extended seat seal life. Top entry construction allows field service and in-line maintenance if necessary. All major components of the check valve are normally made from cast and wrought forms, allowing the use of a variety of widely accepted materials. The full bore to API-6D assures unrestricted flow and allows pigging and hot tapping.

FORGED STEEL, SIDE ENTRY SPLIT BOLTED BODY, SEAT SUPPORTED FLOATING BALL, SOFT OR METAL SEATED, ANTI BLOW-OUT STEM, ANTISTATIC DEVICE, FIRESAFE DESIGN

SEAT INSERT

DISC TO STEM LINKAGE

| 1. VALVE BODY | The body is cast in carbon or stainless steel and is also available in many other CRA. For severe services and large valve sizes it can be internally lined or fully cladded instead of having solid CRA. The internal profile is designed in order to minimize pressure losses, and basic dimensions (face to face and wall thickness) comply with API 609 and ISO5752 standards. Body style can be wafer or wafer LUG type, flanged, or buttweld. Body connections can be provided as per ASME B 16.5 RF or RTJ, as well as BW end or hub connection are available. |

|---|---|

| 2. SEAT INSERT | The seat insert can be proposed with different solutions, against different service severity scenarios. A plastic (PTFE/PEEK/PA/...) insert can be chosen as well as laminated graphite/metallic inserts, for metal to metal seating. The seat insert is located in the body, to enhance the tightness capability, been working in expansion only. For wafer style valves only, it is located on the disc. Seating geometry is of triple eccentric type, ensuring the best result in terms of seating effort against tightness level achievable. |

| 3. DISC | The disc is the main part of the trim and allows fluid control, as well as tight shut off capability. It comes in forged or cast steel ort CRA for diameters up to 12” and in cast steel for larger diameters. Its shape is optimized in order to avoid turbulences and is assisted by a spring in closed position. Each component is verified with Fem-FEA analisys in order to deliver the seating torque uniformly to the seat and ensure the highest rigidity against both seating directions. |

| 4. STEM | The valve is operated through the stem rotation, which hold the pressure thrust and increase the disc stiffness. Stem is connected to the disc through non-shear pins, which increase the torsional resistance of the stem and do not transmit the torque through shear resistance of the pins. |

| 5. STEAM SEAL | The stem is sealed through an O-Ring arrangement for regular temperature applications and mild environments. STEM SEAL An energized lip seal is used for low torque demand and/or cryogenic services. For high temperatures, fire safe design, or when a stuffing box is preferred, a graphite packing is provided, with the top level FE qualifications in order to reduce fluid losses. |

| 6. OPERATOR | The quarter turn operators are worm type gearboxes. The valve can be easily interfaced with electric or linear actuators through standard ISO5211 flange. |

WAFER TYPE BUTTERFLY VALVE

| No. | Name of Part | NAME OF PART | ASTM Specification | |

|---|---|---|---|---|

| JIS | ASTM | |||

| 1 | BODY | CAST IRON | FC 200 | A126 CLASS B |

| DUCTILE IRON | FCD 450 | A536-65-45-12 | ||

| 2 | Disc | DUCTILE IRON | FCD 450 | A536-65-45-12 |

| STAINLESS STEEL | SCS 13 | A351 CF8 | ||

| SCS 14 | A351 CF8M | |||

| 3 | SHAFT | STAINLESS STEEL | SUS 410 | A182 F410 |

| SUS 316 | A182 F316 | |||

| SUS 304 | A182 F304 | |||

| 4 | SEAT | RUBBER | BUNA-N(NBR) | |

| EPDM (1) | ||||

| 5 | SET BOLT | STAINLESS STEEL | SUS 316 | A182 F316 |

| 6 | WORM GEAR BOX | CAST IRON | FC 200 | A126 CLASS B |

| 7 | HAND WHEEL | CAST IRON | FC 200, SGP | A126 CLASS B, A53 |

| 8 | LEVER HANDEL | CAST IRON | FC 200, SGP | A126 CLASS B |

Industries We Serve

Zebco Engineering proudly serves a diverse array of industries, including manufacturing, energy, oil & gas, and more. Our products are designed to meet the highest standards across every sector we support.

Let’s Get Started

Our team is here to help with all your industrial needs. Reach out to us today, and let Zebco Engineering provide the solutions you're looking for.

Need Expert Assistance?

Complete the Form and We'll Reach Out Soon!