High-Quality Check Valves – Top Suppliers & Manufacturers in India

At Zebco Engineering, we proudly offer API-approved check valves for industries like oil, gas, and power. From swing to lift and wafer-type valves, we provide reliable solutions tailored to your needs. With Zebco, you get quality, efficiency, and peace of mind, knowing your operations are backed by durable, trusted valve solutions.

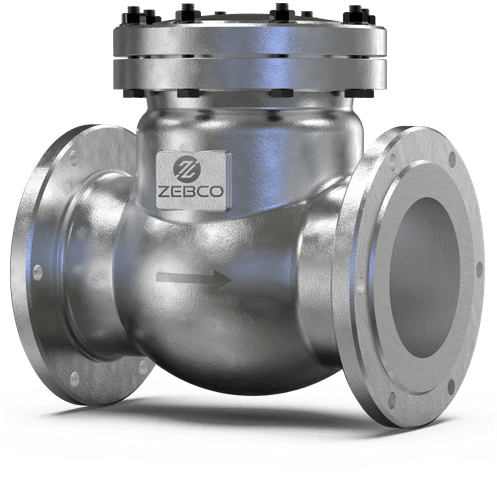

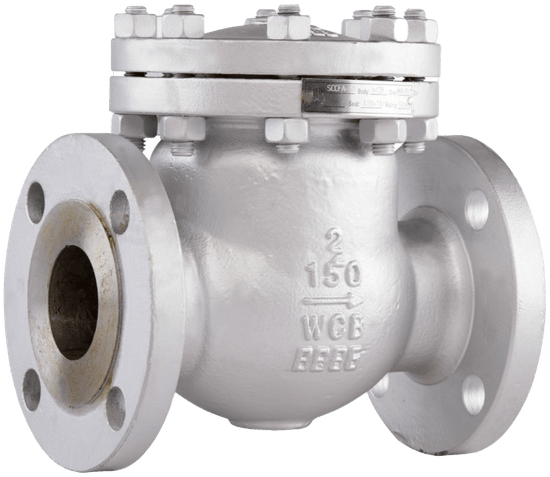

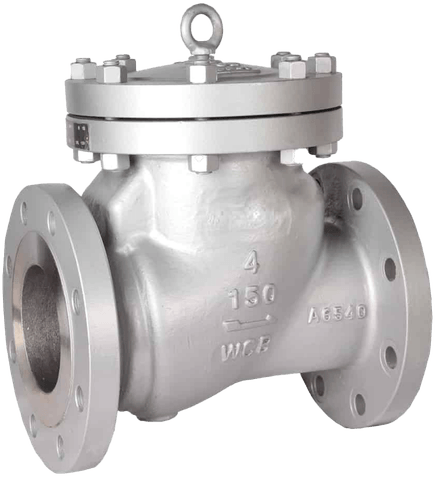

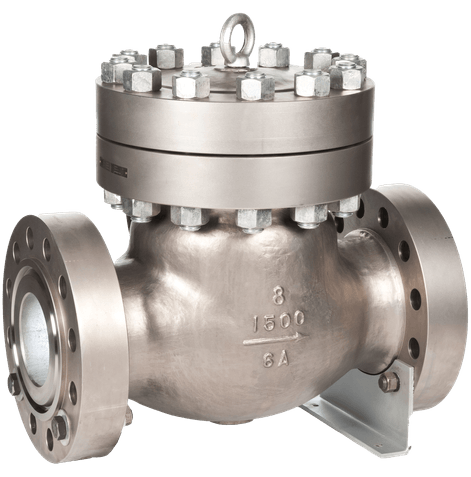

High-Quality Swing Check Valves Manufacturer in India

As a trusted manufacturer in India, Zebco provides robust swing check valves designed for efficient backflow prevention and dependable performance across various industrial applications.

| Design | : | ASME B16.34 / BS 1868 |

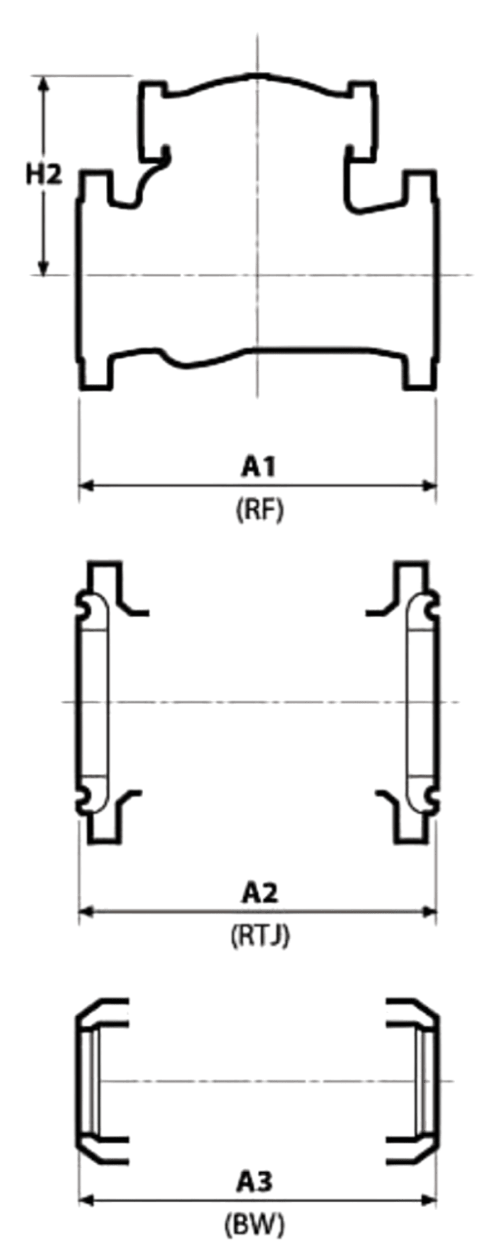

| Face to Face | : | ASME B16.10 / DIN IS / BS |

| End to End | : | BW Type / Flanged End / RTJ |

| Pressure - Temp. Rating | : | ASTM B 16.34 |

| Materials (Body | Bonnet) | : | CS / SS / Alloys / Monel / Hastalloys / Bronze MOC |

| Flange End | : | ASME B 16.5 |

| Test Standard | : | API 598 / BS 6755 |

| Operation | : | Automatic |

| Size | : | 1/2” up to 36“ (15NB - 900NB) |

| Class | : | 150# - 2500# |

CHECK VALVE INTRODUCTION: PREVENTING BACKFLOW AND PROTECTING SYSTEMS

TRUSTED MANUFACTURER, EXPORTER, AND SUPPLIER OF check VALVE IN India

Check valves play a crucial role in keeping fluid systems running smoothly by maintaining unidirectional flow and preventing backflow. Designed to meet strict industry standards like API 594 and ISO 9001, our check valves are built to handle tough applications with reliability and durability.

At Zebco Valves, we’re passionate about delivering high-quality check valves at prices that make sense. Engineered for performance, our valves open with fluid pressure and close securely with gravity or back pressure, ensuring smooth and dependable operations every time. Crafted using premium materials like Carbon Steel, Stainless Steel, and Duplex Stainless Steel, and fitted with top-notch components such as the body, cover plate, disc, and gaskets, our valves are built to last. Whether you’re in oil and gas, petrochemicals, or power generation, Zebco check valves are tailored to meet your specific needs.

Why Choose Zebco Check Valves?

- Superior Quality: Each valve is made with certified, high-quality components to deliver reliable, long-lasting performance.

- Advanced Design: Our valves use gravity and back-pressure activation for a secure seal and seamless operation.

- Customer Commitment: We’re here for you before, during, and after your purchase, providing outstanding support whenever you need it.

WHY YOU SHOULD USE CHECK VALVES IN YOUR INDUSTRIAL SYSTEM

- Long service life

- Easy handling and maintenance

- Stem packing replacement in working conditions

- Prevents Backflow: Automatically stops fluid from flowing in the wrong direction, protecting your equipment and keeping operations efficient.

- Simple and Reliable Design: With fewer moving parts, these valves are easy to install, use, and maintain, saving you time and effort.

- Minimal Pressure Drop: The wide flow path allows for smooth fluid movement, ensuring better system performance with less resistance.

- Perfect for Large Pipelines: Handles high flow rates and large volumes of fluid, making it ideal for bigger systems.

- Versatile Applications: Works well with water, steam, oil, and gas, making it suitable for industries like oil and gas, petrochemicals, and water treatment.

- Built to Last: Constructed with durable materials like Carbon Steel and Stainless Steel, these valves can withstand tough conditions and high pressures.

- Easy to Maintain: Simple access to parts makes maintenance quick and hassle-free, reducing downtime.

- Self-Operating: Works automatically without needing manual operation or external power, offering convenience and reliability.

- Trusted Standards: Designed to meet global standards like API 594 and ISO 9001, ensuring safety and top-quality performance.

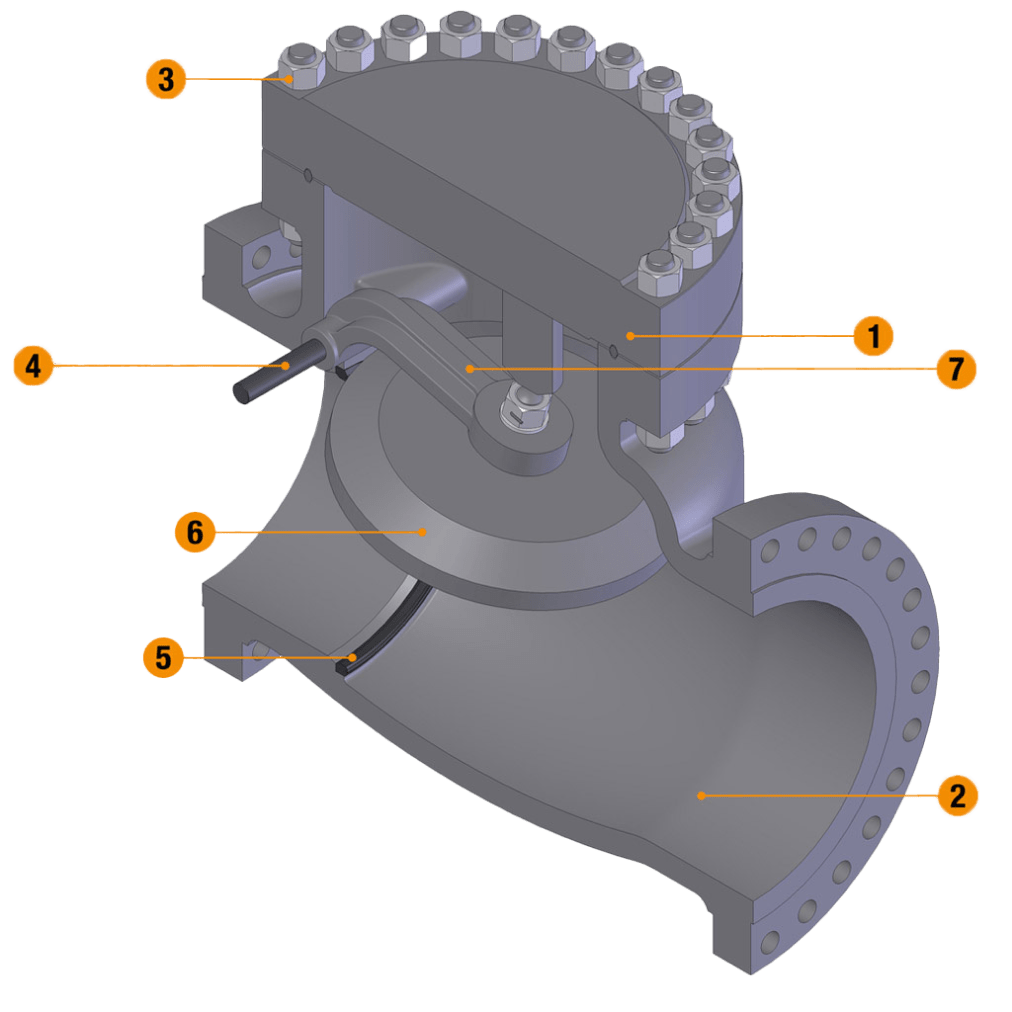

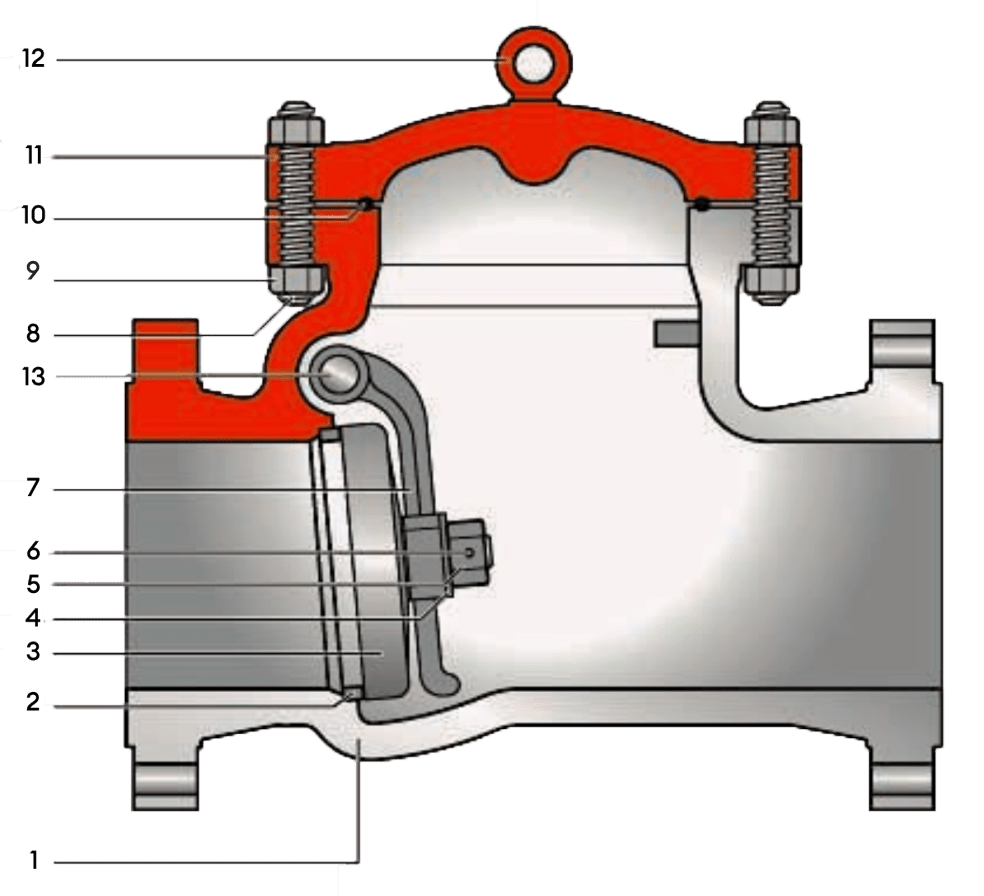

A COMPREHENSIVE LOOK AT CHECK VALVE CONSTRUCTION

The Swing Check Valve is a one-piece body, top entry design for reliable operation and extended seat seal life. Top entry construction allows field service and in-line maintenance if necessary. All major components of the check valve are normally made from cast and wrought forms, allowing the use of a variety of widely accepted materials. The full bore to API-6D assures unrestricted flow and allows pigging and hot tapping.

CAST STEEL, SWING TYPE DISC, RENEWABLE BODY SEAT RING, BOLTED BODY-TO-COVER CONNECTION.

COUNTERWEIGHT CONFIGURATION

“INSIDE PIN” DESIGN FOR “LOW F.E. PURPOSE”

| 1. COVER | The cover is in carbon or stainless steel and is also available in many other CRA. The connection sealing surfaces are raised face or ring joint to suit the valve rating. |

|---|---|

| 2. BODY | The body is in carbon or stainless steel and is also available in many other CRA. It is carefully designed for total reliability, to keep the pressure drops to a minimum and simple maintenance. The basic dimensions, wall thickness, face to face and flanges, comply with the relevant BS, API and ASME standards. The body-to-cover flange is circular. The sealing surface for connection to the cover is recessed in the 150 and 300 Class and ring joint for higher ratings. The body is threaded for a renewable seat and an integral over-travel stop for the disc is incorporated. Two threaded bosses are provided for the location of the hinge pin. Bosses are eventually provided for drain threaded connection. |

| 3. COVER BOLTING | Bonnet studs and nuts are manufactured from alloy steel to the relevant ASTM standard. |

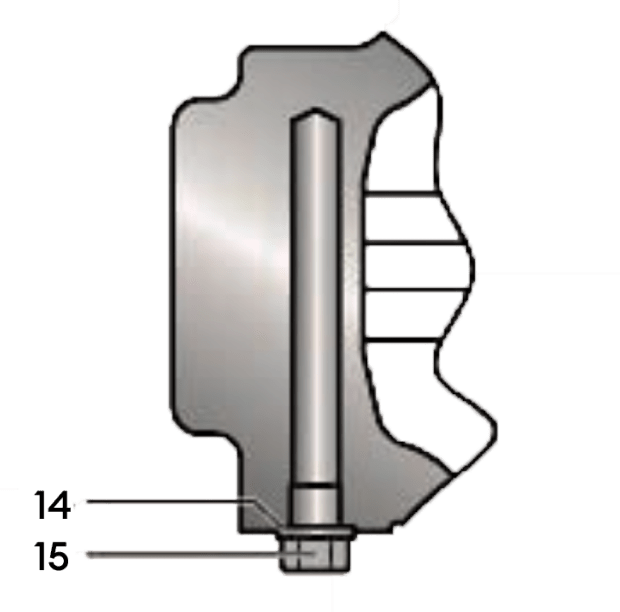

| 4. HINGE PIN | The hinge pin is part of the trim, in forged stainless steel and is machined from ground bar. The hinge pin is locked in the body with two threaded NPT plugs. The pin can be removed for maintenance of the valve. |

| 5. SEAT RING | Welded-in-seat ring are supplied as a standard. The rings are part of the trim of the valve. For threaded solution, the outer diameter is threaded and its bore is notched for easy installation and dismantling. Special attention is given to the seating face which is ground and lapped, for a perfectly tight seal. |

| 6. DISC | The disc is part of the trim and is in forged or cast steel. On the back face there is a threaded spigot for the connection to the hinge arm by a nut and cotter pin. The seating surface is ground and lapped. |

| 7. HINGE | The hinge is made by forged steel and in cast steel. |

CARBON STAINLESS STEEL FULL PORT CHECK VALVE

| No. | Name of Part | ASTM Specification | ||||||

|---|---|---|---|---|---|---|---|---|

| CARBON STEEL | HIGH-TEMPERATURE SERVICE | LOW TEMPERATURE SERVICE | STAINLESS STEEL | |||||

| 1 | BODY | A216 - WCB | A217-WC6 | A217-WC9 | A217-C5 | A352-LCB/LCC/LC2/LC3 | CF8M | CF8C |

| 2 | BODY SEAT RING | A105 + HARD FACE | A182-F11 | A182-F22 | A182-F5A | A182-F304 | F316 | F347 |

| 3 | DISC | A216 - CR13 | A217-WC6 | A217-WC9 | A217-C5 | A352-LCB/LCC/LC2/LC3 | CF8M | CF8C |

| 4 | DISC WASHER | AISI 304 | ||||||

| 5 | DISC NUT | AISI 304 | ||||||

| 6 | DISC PIN | AISI 304 | ||||||

| 7 | ARM | A216 - WCB | A217-WC6 | A217-WC9 | A217-C5 | A352-LCB/LC2/LC3 | CF8M | CF8C |

| 8 | BONNET BOLT | A193-B7M | A193-B16 | A193-B16 | A193-B16 | A320-L7M | A193-B8 | A193-B8 |

| 9 | BONNET NUT | A194-2HM | A194-4 | A194-4 | A194-4 | A194-7M | A194-8 | A194-8 |

| 10 | BONNET GASKET | SPIRAL WOUND + GRAPHITE / RING JOINT | ||||||

| 11 | COVER | A216 - WCB | A217-WC6 | A217-WC9 | A217-C5 | A352-LCB/LCC/LC2/LC3 | CF8M | CF8C |

| 12 | EYE BOLT | C5 | ||||||

| 13 | HINGE PIN | A276 - 410 | A276-410 | A276-410 | A276-410 | A276-304 | F316 | F347 |

| 14 | GASKET | GRAPHOIL | ||||||

| 15 | PLUG | C5 | F316 | F316 | ||||

Industries We Serve

Zebco Engineering proudly serves a diverse array of industries, including manufacturing, energy, oil & gas, and more. Our products are designed to meet the highest standards across every sector we support.

Let’s Get Started

Our team is here to help with all your industrial needs. Reach out to us today, and let Zebco Engineering provide the solutions you're looking for.

Need Expert Assistance?

Complete the Form and We'll Reach Out Soon!