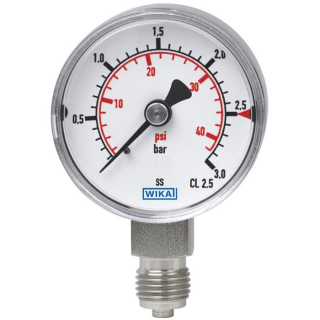

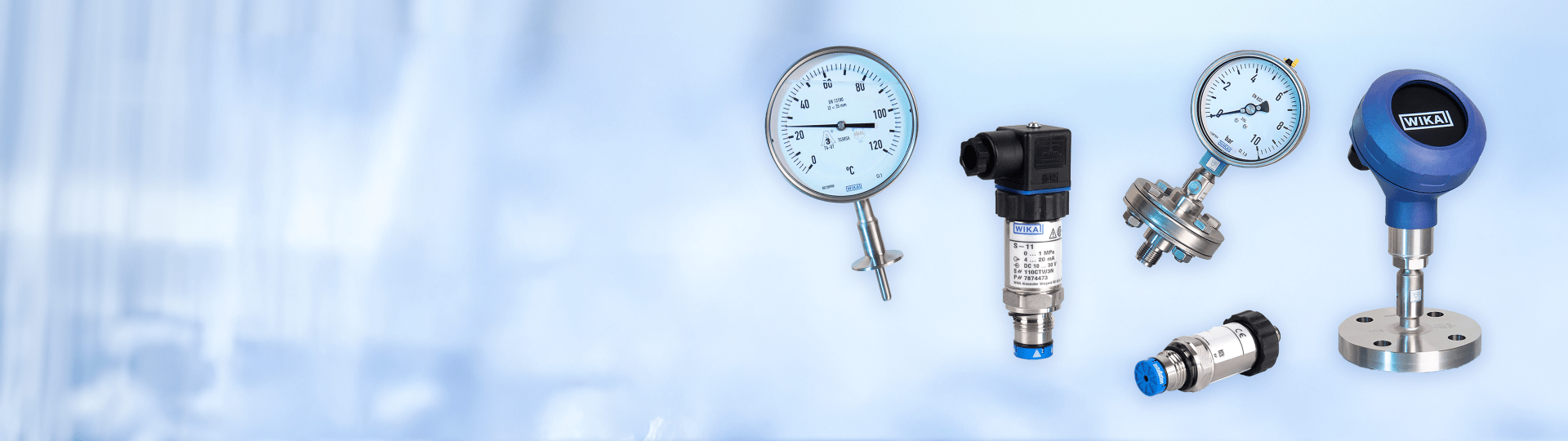

Wika Pressure Gauge

This high-quality Bourdon tube pressure gauge has been designed especially for the process industry.

The use of high-quality stainless steel materials and the robust design are geared to applications in the chemical and process engineering industries. Thus the instrument is suitable for liquid and gaseous media, also in aggressive environments.

Scale ranges of 0 ... 0.6 to 0 ... 1,600 bar [0 ... 10 to 0 ... 20,000 psi] ensure the measuring ranges required for a wide variety of applications.

WIKA manufactures and qualifies the pressure gauge in accordance with the standards EN 837-1 and ASME B40.100. As a safety function, this instrument has a blow-out device with blow-out plug on the back of the case. In the event of a failure, overpressure can escape there.

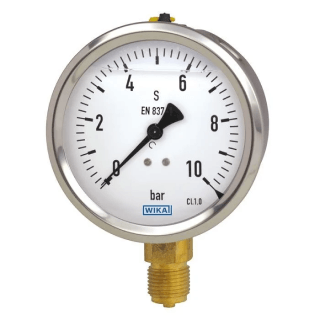

The model 233.50 with liquid-filled case is suitable for high dynamic pressure loads and vibrations.

The QR code on the dial allows instrument-specific information such as the serial number, the order number, certificates and other product data to be retrieved from the internet easily and in the long term.

Special Features

- External zero adjustment (optional)

- Stainless steel case & measuring system

- Socket directly welded to case

- Dry and liquid filled version

- Standard followed EN 837-1 (for NS 100, 150 & 250 mm)

- CE marking (as per PED 97/23/EC) (for NS 100 mm & 150 mm)

Application

- Increased safety requirements for personal protection

- With liquid-filled case for applications with high dynamic pressure loads or vibrations (model 233.30)

- For gaseous and liquid aggressive media that are not highly viscous or crystallising, also in aggressive environments

- Oil and gas industry, chemical and petrochemical industries, power engineering and also water and wastewater technology

- Environments & gaseous or liquid media that will not obstruct the pressure system.

- Hydro-cleaning machines

- Presses

- Engine compressors

- Turbines

- Diesel engines & Refrigerating plants

- Suitable for corrosive

- Conventional & nuclear power plants

Features and Benefits

- Dial sizes: 40, 50, 63, 80, 100, 130 and 160 mm

- Wetted parts copper alloy, stainless steel or monel

- Process connections e.g. G ¼, G ½, ½ NPT, 7-16 UNF, M20x1,5 etc.

- Measuring ranges from 0…6 mbar to 0….1600 bar

- Scales in bar, mbar, psi, kPa, MPa, mmH2O, inHG etc.

- Industry standards: EN837 and ASME B40.100

- Approvals: ATEX, Lloyd´s register, NACE MRO103/175, EAC

- Damping fluids glycerin, silicone, paraffin

- Safety gauge: S1 or S3 (EN837) or solid front (ASME B40.100)

- Differential pressure gauges

- Pressure gauges with mechanical or inductive contacts

- Customer specific pressure gauges for many applications

More choice, more variants. Find your product in the product selector.

Let’s Get Started

Our team is here to help with all your industrial needs. Reach out to us today, and let Zebco Engineering provide the solutions you're looking for.

Need Expert Assistance?

Complete the Form and We'll Reach Out Soon!